Reliable Solutions

Your Partner in Mechanical Excellence

At our company, we focus on delivering safe and high-quality mechanical services. With a dedicated team in Kentucky and Florida, we specialize in boiler maintenance, piping installations, and HRSG maintenance. Your project’s success is our top priority, and we strive for excellence in every task we undertake.

Our Project Capabilities

We take pride in our diverse range of projects, focusing on mechanical contracting in various sectors. Our expertise covers everything from boiler maintenance to intricate piping installations. Each project reflects our commitment to safety and quality, ensuring client satisfaction with every detail.

Showcase

Project Gallery

Our Projects

Explore Our Mechanical Success Stories

Discover the diverse range of projects we’ve successfully completed across various sectors. Our work highlights our dedication to quality and safety, ensuring we meet every client’s needs.

TAMPA ELECTRIC COMPANY – Big Bend Power Station Unit No. 3, Apollo Beach, FL

Feedwater Heater Replacement: Pro Serv provided construction services, including cutting and machining nozzle piping, removing two existing Unit 3 feedwater heaters, installing owner-supplied feedwater heaters, and restoring piping.

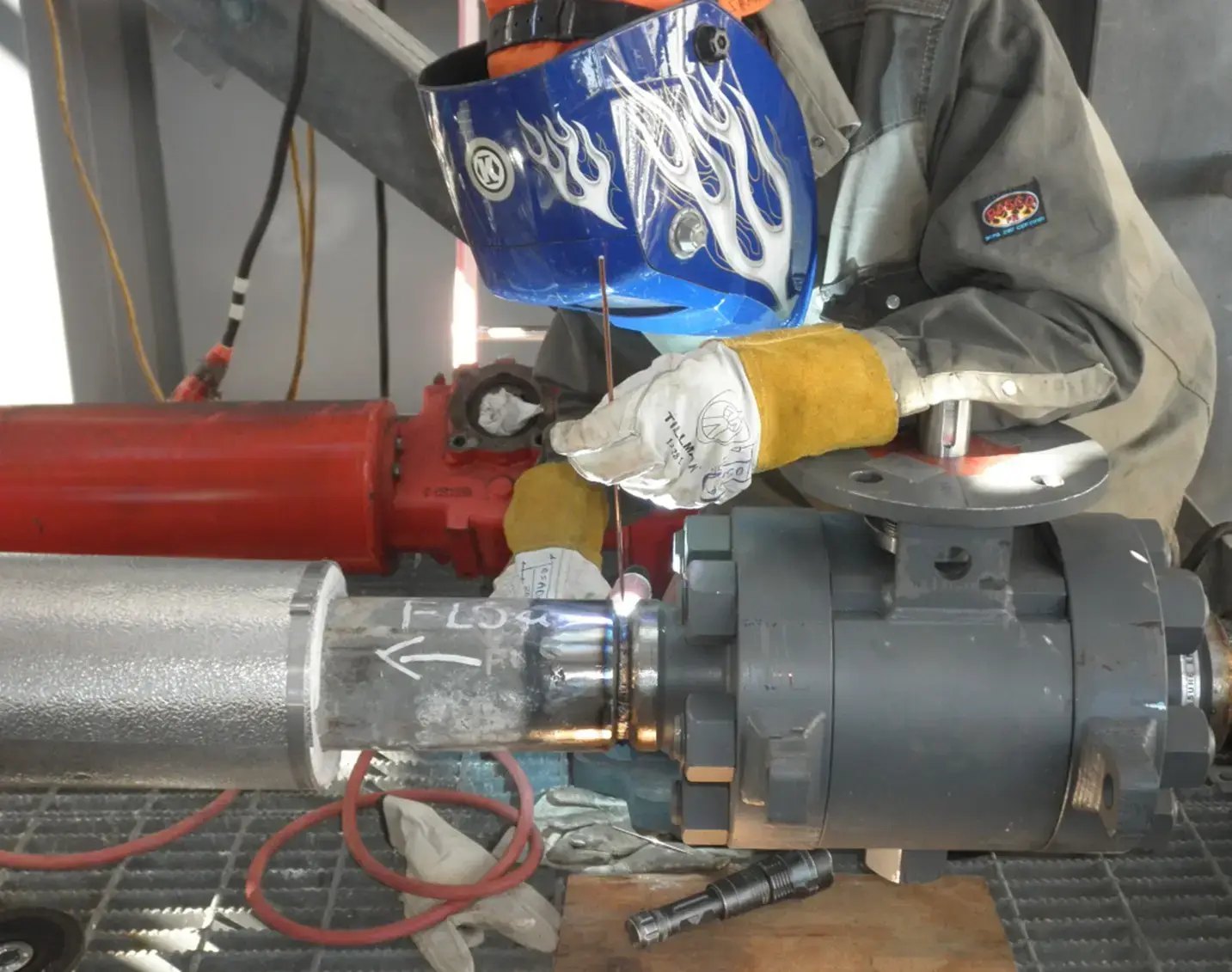

SIEMENS ENERGY, INC. – Lordstown, OH

P91 Chemical Clean Port Cap Installation: Pro Serv removed existing weld neck flange, fit up and welded new P91 cap, provided preheat, PWHT, radiography services, and removed/replaced insulation.

WHEELABRATOR – McKay Bay, Tampa, FL

Unit 2 Fabric Filter Hopper Replacement: Pro Serv removed the existing hopper and installed a new one, modified the access door, and mounted vibrators during a three-day outage.

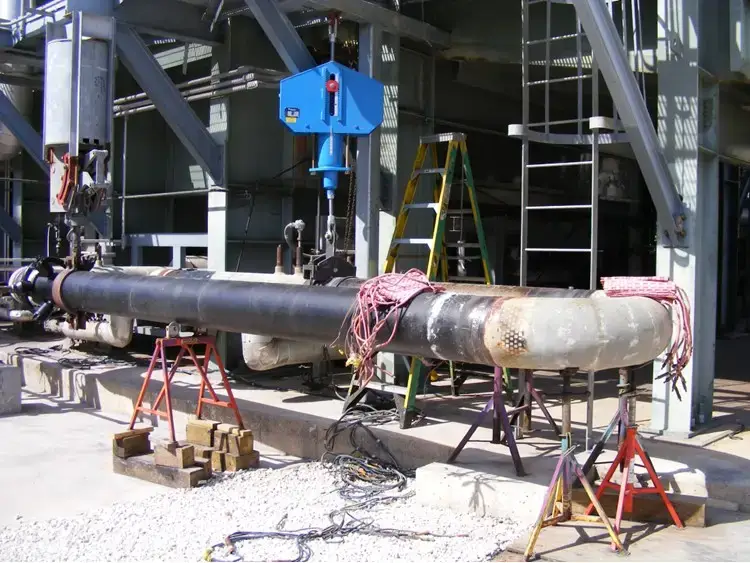

SEMINOLE ELECTRIC – Midulla Generating Station, Bowling Green, FL

Main Steam and Hot Reheat P91 Lateral Replacement: Field machining, cutting and beveling, preheat, bake-out, PWHT, fit up and weld out, and NDE – Phase Array testing.

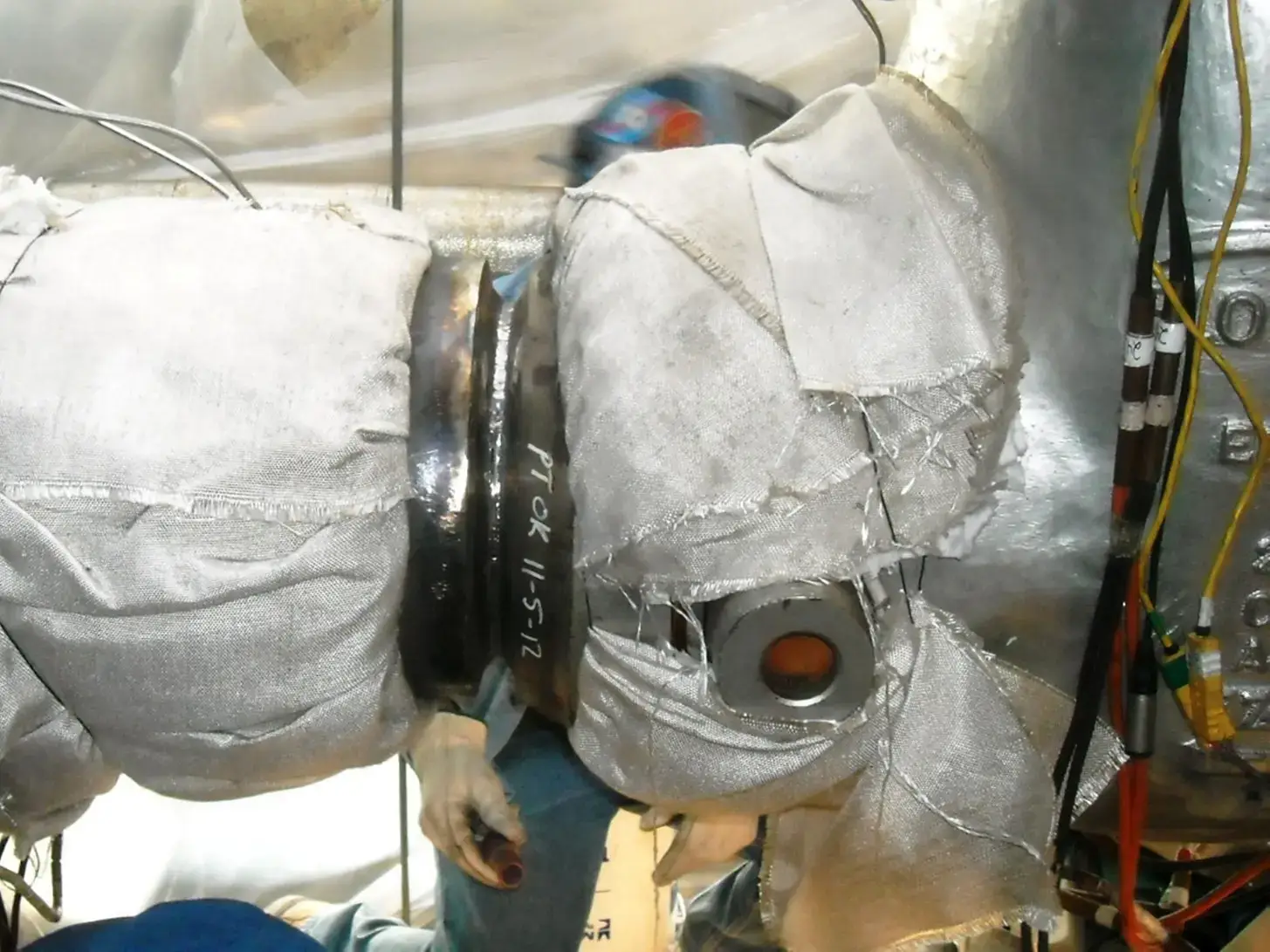

PANDA – Hummel Station, Shamokin Dam, PA

HRH Valve Weld Reinforcement: Installed weld build-up as directed by the valve manufacturer (CCI), provided preheat and PWHT services, and replaced insulation.

TAMPA ELECTRIC COMPANY – Bayside Power Station, Tampa, FL

Blowdown Tank Replacement: Pro Serv removed four existing blowdown tanks and installed four new ones, restoring all pipe connections.

AUSTIN ENERGY – Sand Hill Energy Center, Del Valle, TX

Supply and Install Cooling Tower Supply Piping: Designed and supplied fiberglass piping to replace carbon steel, removing and replacing one unit at a time.

TAMPA ELECTRIC COMPANY – Big Bend Power Station Unit No. 4, Apollo Beach, FL

Feedwater Heater Replacement: Removed existing feedwater heaters, installed owner-supplied replacements, and restored piping.

AUSTIN ENERGY – Sand Hill Energy Center, Del Valle, TX

Unit 5 HRSG Maintenance Outage: Replaced four ASME Section I valves, performed iceblast cleaning, cleaned welds for NDE examination, replaced duct burner gaskets, and installed weather protection for steam drum instrumentation.

TAMPA ELECTRIC COMPANY – Big Bend Power Station Unit No. 2, Apollo Beach, FL

Boiler Superheat Replacement: Pro Serv replaced 81 superheat tube platens, performed 486 tube welds and 200 waterwall tube welds, ensuring reliable boiler performance.

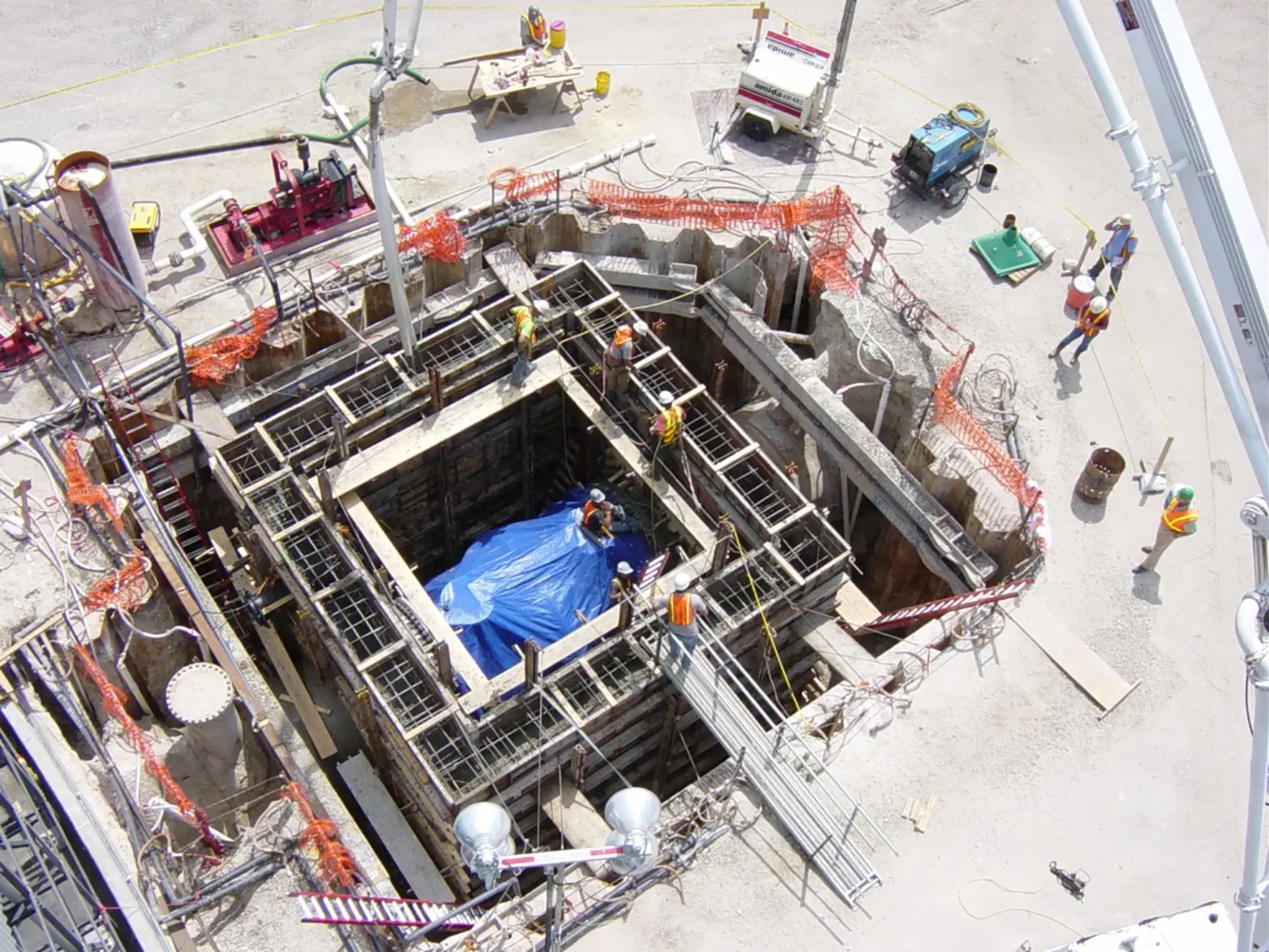

SOUTHERN COMPANY SERVICES – Plant Stanton, Orlando, FL

P91 Main Steam Valve Replacements: Replaced four 24” P91 main steam valves and one 14” P91 steam valve in a 14-day outage period, with preheat, PWHT, and 100% radiography.

SOUTHERN COMPANY – Plant Stanton, Orlando, FL

Cooling Tower Fan Speed Reducer Replacement: Pro Serv responded to an emergency need to replace one cooling tower fan speed reducer.

NORTHERN STAR GENERATION / CAMS – Polk Power Partners, Mulberry, FL

Entrainment Vessel Replacement of Internals: Cut access into the vessel shell, removed old trays and internals, installed new trays and internals, and restored the vessel shell.

UNITED STATES SUGAR CORPORATION – Breakthrough Project, Clewiston, FL

Evaporator Building Piping: Supplied and installed 32,000 lf of large bore piping, 15,000 lf of small bore piping, 1650 control valves, 583 manual valves, 28 pumps, provided insulation for all piping and equipment, and offered start-up assistance.

WHEELABRATOR – South Broward, Fort Lauderdale, FL

Powdered Activated Carbon Injection System: Installed equipment foundations, set owner-supplied carbon silo, supplied and installed piping for carbon, water, and air, and installed electrical equipment and wiring.

DUKE ENERGY – Anclote Power Station, Holiday, FL

Cooling Tower Debris Filter Installation: Pro Serv installed debris filter equipment to enhance system performance.

TAMPA ELECTRIC COMPANY – Bayside, Tampa, FL

HRSG Desuperheater Piping Modifications: Cut existing P22 piping, machined bevel cuts, installed new P22 pipe supplied by TECO, and restored supports and engineered hangers.

CITY OF LAKE WORTH – Tom G. Smith Power Facility, Lake Worth, FL

HRSG Economizer Replacement: Removed existing economizer tube modules, installed new owner-supplied modules, installed boiler drains and vents, hydrotested, and assisted the chemical cleaning contractor.

Get in Touch for Your Project Needs

Ready to discuss your project? We’re here to provide expert support and answer any questions. Our team is committed to delivering top-notch mechanical services tailored to meet your needs.